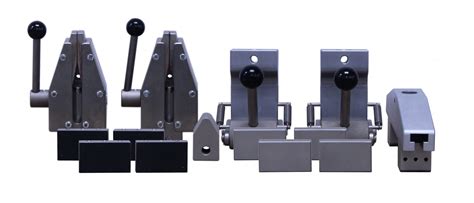

jaws grip for tensile testing machine|tensile grip jaw testing : exporters Grips for Instron tensile test machines. Tensile grips are designed to pull the sample apart or to a specified point of elongation. The most common styles are mechanical vise wedge and pneumatic grips. We can help you select the optimal grip or jaw taking into full account the nature of your test sample. We can inform you of the tradeoffs . A outlet without name implicitly has the name "default".. In a parent component using , we need a way to pass multiple slot content fragments, each targeting a different slot outlet.This is where named slots come in.. To pass a named slot, we need to use a element with the v-slot directive, and then pass the name of the slot as .

{plog:ftitle_list}

Resultado da 6 de fev. de 2023 · Profile of Everton and their manager Sean Dyche who replaced Frank Lampard in January 2023. Latest next manager odds and betting information.

Tensile grips are used for uni-axial material testing where a sample is pulled apart from two ends. There are many variations of tensile grips for universal testing machines based on the .

ADMET offers a range of wedge grips to suit your needs: Lower Capacity: Spring-operated with a handle for opening and closing the jaws. Higher Capacity: May feature handle . The design and development of jaw grip for circular tensile test samples in a universal mechanical tester were under-taken in this work. In developing economies, the cost of acquiring laboratory . Grips for Instron tensile test machines. Tensile grips are designed to pull the sample apart or to a specified point of elongation. The most common styles are mechanical vise wedge and pneumatic grips. We can help you select the optimal grip or jaw taking into full account the nature of your test sample. We can inform you of the tradeoffs .TestResources manufactures and supplies universal test machines, tensile testers, dynamic testing machines, and much more. Call us today (800)430-6536. . Recommend appropriate grips and fixtures; Compare machines and .

Manufacturer of Tensile Testing Machine Grips - Tensile Testing Machine Jaws And Grip, Tensile Machine grips offered by Suison Scientific Instrument, New Delhi, Delhi. X. Suison Scientific Instrument. Budh Vihar, New Delhi, Delhi | GST 07AWPPS1856B1ZB. is .This page shows our range of wedge grips suitable for a wide range of tensile test machines. top of page. Tailored Test Solutions. . This action minimises the preload applied to the sample by the grips. The jaws are spring loaded to the capstan rod, this eliminates backlash and allows the jaws to move when load is applied. .

tensile grips for testing

Call us at 312-666-0595 Send us an email [email protected]. Submit a Contact Form. Business Hours Monday-Friday 8:00 am - 4:30 pm CST. Location JLW Instruments 14 N Peoria St. Suite B-101 Chicago, IL 60607. JLW Instruments sells and calibrates force instruments, material testing machines, torque instruments, hand dynamometers, pinch gauges, .Pneumatic grips use air to actuate the grip jaws and provide a constant and repeatable lateral force on the sample specimen. There are many different types of pneumatic grips that are used for tensile testing including vise grips, wedge grips, and certain styles of rope grips. Sjogren tensile testing replacement jaws feature our proprietary tooth pattern, providing superior durability and grip while remaining compatible with your current equipment. About Sjogren Founded in 1927 by Oscar Sjogren, Sjogren Industries has long been an innovator in designing and manufacturing customized solutions for the wire tooling trades.

yarn testing machines. Tensile Jaws : TestResources offers test fixtures, tensile jaws, clamps, and grips that are compatible with our universal test machines. Grip Jaw Coverage: Ensure the grip jaws cover at least three-quarters of your specimen’s surface area, as recommended by most tensile testing standards. This maximizes grip and minimizes slippage. ADMET offers a variety of grip jaw sizes to accommodate different specimen dimensions. Jaw Surface Match: The type of jaw surface also plays a role .3 Specimen grips for tensile tests Specimen grips form the mechanical link between the specimen and the testing machine. Their function is to transfer the movement of the crosshead or piston to the specimen and transmit the test load generated in the specimen to the load cell installed on the load frame. The test most frequently applied is the .THE RIGHT PRODUCT WITH SERVOSIS . SERVOSIS is a Spanish company dedicated to the design, development and manufacture of testing machines, electronic and mechanical systems for quality control and materials analysis, servo systems, industrial process and machinery controls, robotics, measurement and data acquisition systems.

How do we conduct a tensile strength test? To perform a tensile test, insert a sample of a material between two fixtures or grips. Begin the test with a specimen of known dimensions, including length and cross-sectional area. Apply force to the material through the use of a universal test machine (UTM), sometimes referred to as a test stand or .

Easy-to-use mechanical grips, designed for tensile testing of low-resistance sheet materials. . incorporated in a Universal Testing Machine Jaws for MDM / 0,1-S Grips: supply of 1 set = 4 jaws Model Surface Finish Clamping . Easy-to-use mechanical jaws, designed for tensile testing of sheet materials with low resistance upThe specimen grip is opened and closed via buttons on the testing machine. The optional foot pedal unit or machine remote control can be used for additional operating convenience. . (no differential movement of the jaws) the test .Materials Test Grips Industry-leading grip designs set the standard for ease-of-use, accuracy and repeatability. Options for specialized applications such as high-temperature, low-cycle fatigue and fracture are available.The newly produced jaws grips were subjected to test on a Tensile Testing Machine [as shown in Figure 3(a)] following the predetermined mounting setup shown in Figure 3(b) to conduct several tensile tests on a circular JMMCE O. .

These heavy duty self-tightening grips with a capacity range of 50 lbf to 2,000 lbF (250 N to 9 kN) are ideal for tensile testing of a wide range of materials. Select from rubber or serrated, hardened steel jaw faces. The jaws ride on rollers instead of sliding along the surface of the housing, as with conventional wedge grips. This unique design prevents jamming and .Depending on the dimensions and texture of the material, different grip types and jaw face surfaces may be required in order to successfully grip the specimens. Grips are available in a wide variety of force capacities and with rubber-coated, smooth, serrated, and other surface types. . Tensile testing machines are available in a variety of .

Products > Tensile Grips > Vise . Vise Grips are the most basic type of grip used by a Universal Testing Machine(UTM) for tensile testing. There are two main types, Low-Profile and U-Style. The Low-Profile version is lower cost but has a limitation on the width of the grip face inserts. The U-style is more standard and can accommodate larger . Tensile testing grips include self-tightening grips, pinching, webbing grips, rope and thread grips, hydraulic grips, wedge grips, pneumatic grips and manual vise grips. The selection of the most suitable tensile grips to effectively secure the samples is essential in obtaining accurate measurements of tensile properties.The TA229 pneumatic grips are a lightweight grip option for tensile strength testing. Its opening range maximum is 10 millimeters (mm), depending on the jaws used. TA232 Pneumatic Tensile Strength Tester Grips. The TA232 tensile strength tester grips have a 1/8-inch internal thread pneumatic connection and 16-kilonewton (kN) clamping force.Tensile testing with strain measurement techniques that can determine critical material properties including elastic modulus, tensile strength, elongation at break, and Poisson’s ratio. MTS provides testing systems, mechanical testing systems, simulation systems and sensing solutions to researchers, developers and manufacturers worldwide.

The low-force 2716 Series wedge grips are ideal for static tensile testing on a wide range of materials including plastics, elastomers, and metals. . Variety of jaw face sizes and surfaces available; Quickly change faces without tools; Options for testing conditions up to 350°C (660°F)

Overview –tensile grips Tension grips Form-fit Force-fit (Frictional grips) self-tensioning Pincer grip Wedge type grip Excentric self- and external-tensioning Hydraulic wedge type grip Screw type wedge action grip external-tensioning Pneumatic grip Hydraulic Vice grip Bollard grip „Specimen holder“ www.hegewald-peschke.comTestResources manufactures and supplies universal test machines, tensile testers, dynamic testing machines, and much more. Call us today (800)430-6536. . for universal testing machine how to use vice grips for wire grippers wire cable gripper pneumatic gripper .dwg tension compression gripper tensile gripper jaws wire gripper fixture tensile .

TestResources manufactures and supplies universal test machines, tensile testers, dynamic testing machines, and much more. Call us today (800)430-6536. Tension Wedge Grips for Rebar Testing

tensile grips for jaws

Abra sua Conta PJ. Crédito para Pessoa Jurídica. Saiba tudo sobre o Pix. Empreendedor Pessoa Jurídica Soluções para ajudar a sua empresa a crescer. Soluções para ajudar a sua empresa a crescer. Empreendedor Pessoa Física Para você que é empreendedor mas ainda não tem um CNPJ. Para você que é empreendedor mas ainda não tem um CNPJ.

jaws grip for tensile testing machine|tensile grip jaw testing